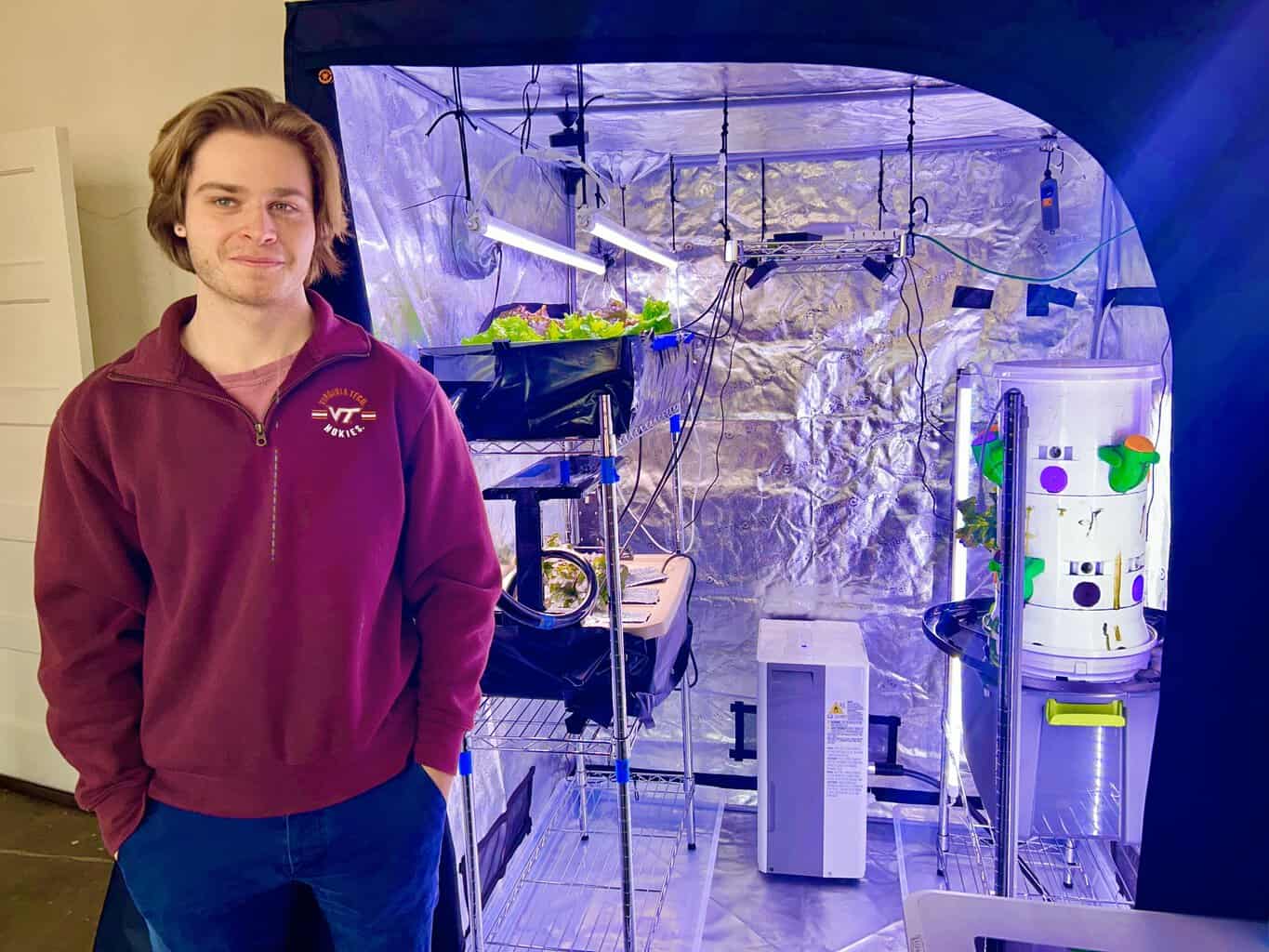

Vegg Inc. harvests first crop at Jefferson

By WILLIAM PAINE

Patriot Publishing

The old Jefferson Elementary School, which has stood vacant for several years, served as the site for the first ever lettuce crop to be grown with the assistance of carbon capture technology.

“We’re harvesting lettuce which has been growing for about a month with recycled CO2,” said Vegg Inc. Director of R & D Alexander (Xander) Yurista. “There’s a device in the room next door that’s pulling CO2 out of the air.”

MOVA Technologies, which maintains offices on West Main Street, as well as a lab on Commerce Street, developed this new technology, which filters CO2 from the atmosphere and then stores the CO2 in tanks.

This “captured” CO2 was pumped into a 5 X 5 grow tent thereby raising the CO2 levels fivefold. Plants grow faster with elevated levels of CO2 and supplementing CO2 levels is a common practice for many industrial greenhouse operations.

The difference is that other indoor farming operations use CO2 produced by burning fossil fuels, thereby causing additional CO2 to be added to the atmosphere. The filtration system developed by MOVA Technologies and put into use by Vegg Inc. takes Carbon Dioxide from the air without producing more CO2 in the process.

“We’re the only ones doing the Climate Smart concept,” said Luke Allison Vegg Inc.’s Chief Development Officer. “This is a huge leap forward because of the fact we’re not burning fossil fuels to get the carbon dioxide that is needed in the Controlled Environmental Agriculture (CEA) industry. Direct Air Capture is not just for the CEA industry but can also be applied to the bottling industry. Sodas and beers all require carbon dioxide.”

Vegg Inc. owns the Jefferson School Building, where the lettuce growing experiment took place but will rely on using the selective air capture technology developed by MOVA Technologies. The companies are separate entities that share many of the same employees.

Last summer, MOVA Technologies secured a $200,000 grant from the Department of Energy to implement a pilot program using this newly developed Direct Air Capture system.

“We acquired the building two years ago and today’s the big day because we didn’t want to raise a whole bunch of money and spend a whole bunch of money until we knew that the idea was going to work,” said MOVA founder and President Steve Critchfield. “Well, the idea works. Today is the harvest. We know that the conceptual idea works, so now it’s worth spending the money and putting the business plan in place.”

Before Vegg Inc. acquired the Jefferson School, the Town of Pulaski secured a Brownfields Grant in order to extract asbestos and lead paint from the interior, though some still remains in the building’s basement level.

Both the Town and the county then loaned Vegg Inc. $50,000 a piece to buy the property. Out of the $100,000 loaned, Vegg Inc has paid back $25,000.

“We’ll pay another $25 to $50,000 this year as it all gets built,” said Critchfield. “The nice thing is both the county and the town support the Climate Smart idea.”

Though there is much renovation work yet to be done, employees of Vegg Inc. have already done some work on the interior of the building.

“I wish you could have seen this place four months ago,” said Luke Allison. “Plaster was falling off the walls and there was lots of trash, broken bottles and human waste throughout. We’ve also rewired much of the building as we didn’t have electricity when we started.”

By renovating the Jefferson School and not building an entirely new facility, Critchfield and company believe that this building will once again establish ties to the surrounding community, as well as reducing neighborhood blight.

Luke Allison added that constructing a brand-new building would result in the production of large amounts of CO2, which goes against the spirit of Vegg Inc.’s operation.

Renovating and repurposing this 30,000 square foot structure won’t be cheap, though. Critchfield estimates the cost to be between 3 and 4 million dollars.

“Now that this has been proven we’re going to start raising money ASAP to get this thing done,” said Critchfield. “First the front of the building, then the auditorium and finally the fire damaged wing of the old Jefferson School.”

Critchfield envisions Pulaski County as being part of a growth hub, similar to the Research Triangle in North Carolina.

“Roanoke, Virginia Tech and Carillion already have the biomedical hub,” said Critchfield. “Blacksburg has the unmanned vehicles, AI, and Cybersecurity software. That’s hub two. We need a third hub. With all of the climate smart things that are going on in this town, MOVA, Vegg, Trova … Volvo going into electric vehicles. We’re literally moving towards a climate smart cluster. So now you have all three clusters. If you get all three sectors moving, you have a growth hub, which is what the whole country wants. We’re two thirds of the way there. Let’s get this third one, a Climate Smart Hub here in Pulaski County.”

April 5, 2024 @ 11:13 am

Do they sell the produce? If so, where?